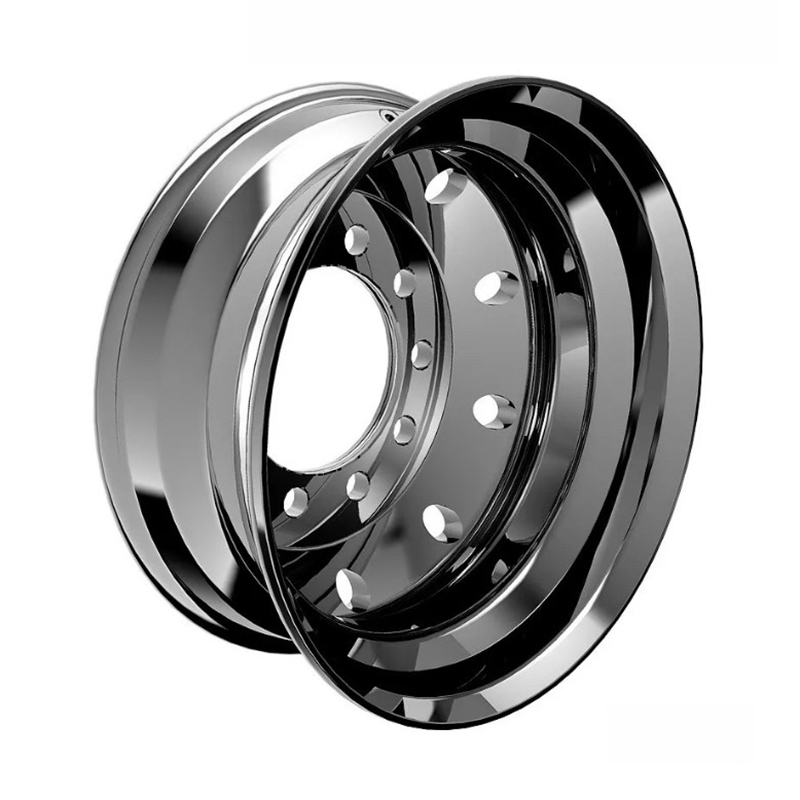

Commercial Vehicle Coach And Truck Forged Alloy Wheels

Forged aluminum alloy commercial truck and coach wheels solve cracks and airtightness problems. It directly avoids the problem of rim cracks and air leakage caused by excessive steering torque impact. The steering wheel installed on the steering bridge (front axle) deflects a certain angle relative to the longitudinal axis of the car to complete the car turning, changing lanes and other actions. The most terminal executive security component in the car steering system. The partial thickening and strengthening (hard reinforcement) of the steering force part is a powerful guarantee to pass the German TUV certification to reach 4 million revolutions and exceed the national standard certification by 4 times. Better stability, lighter maneuverability, greater angle of agile steering, and safer driving environment are the promise of safety to users.

Solve the problem of cracks caused by frequent high-speed impacts under multiple stress environments. It completely avoids the problem of cracks in the mounting surface and window parts caused by multiple forces such as driving force, friction with the ground, and resistance during rolling. The intelligent process of straight forging forming perfectly guarantees the integrity and uniformity of the raw material composition. Making the material organization closer and higher mechanical properties will have better resistance to impact and impact is a manufacturing commitment to users.

It solves the deformation and cracks caused by the heavy load and strong pressure on the rim when the high load and large load-bearing up and down slopes are under bad road conditions. By improving the production process, double load-bearing ribs are added to the circumference of the wheel to ensure roundness and improve product toughness. The total load of a single wheel exceeds 4 tons. Higher carrying capacity, more intuitive benefits, and a safe and powerful guarantee of the maximum load limit of the vehicle, drag and run to earn peace of mind is a heartfelt promise to users.